Tire Maintenance & Safety

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

Did you know National Tire Safety Week is coming from June 24 to July 3? Too often, in too many cases, drivers don’t give much thought to their tires. They’re black round, they hold air, and for many drivers, that’s about as far as their engagement with tires goes, unless something goes wrong and they find themselves stranded by the side of the road with a flat (or worse). Tires are the only point of contact between your vehicle and the pavement, and you shouldn’t neglect them any more than you would your car’s engine or any other system.

In the course of this blog, we hope to give you the information you need to make sure that your tires are in great condition, including the P.A.R.T. formula, which includes:

P: Pressure, as in “check inflation pressure monthly”

You already know what this means if you’ve ever ridden a bicycle with a tire going flat. It’s like you’re trying to pedal through wet sand, and underinflated tires put that same kind of stress on your vehicle’s tires and drivetrain. Underinflated tires mean increased rolling resistance, more fuel use, and compromised handling and braking performance. It can also mean excessive heat buildup in a tire’s internal construction, possibly leading to tire failure. Rubber is slightly porous, and air can seep through tire walls and around the valve stem, sometimes as much as a couple of pounds of monthly inflation. That’s why monthly inflation pressure checks (with a good, reliable gauge) are so important.

A: Alignment, as in “have your alignment checked by a dealer or technician”

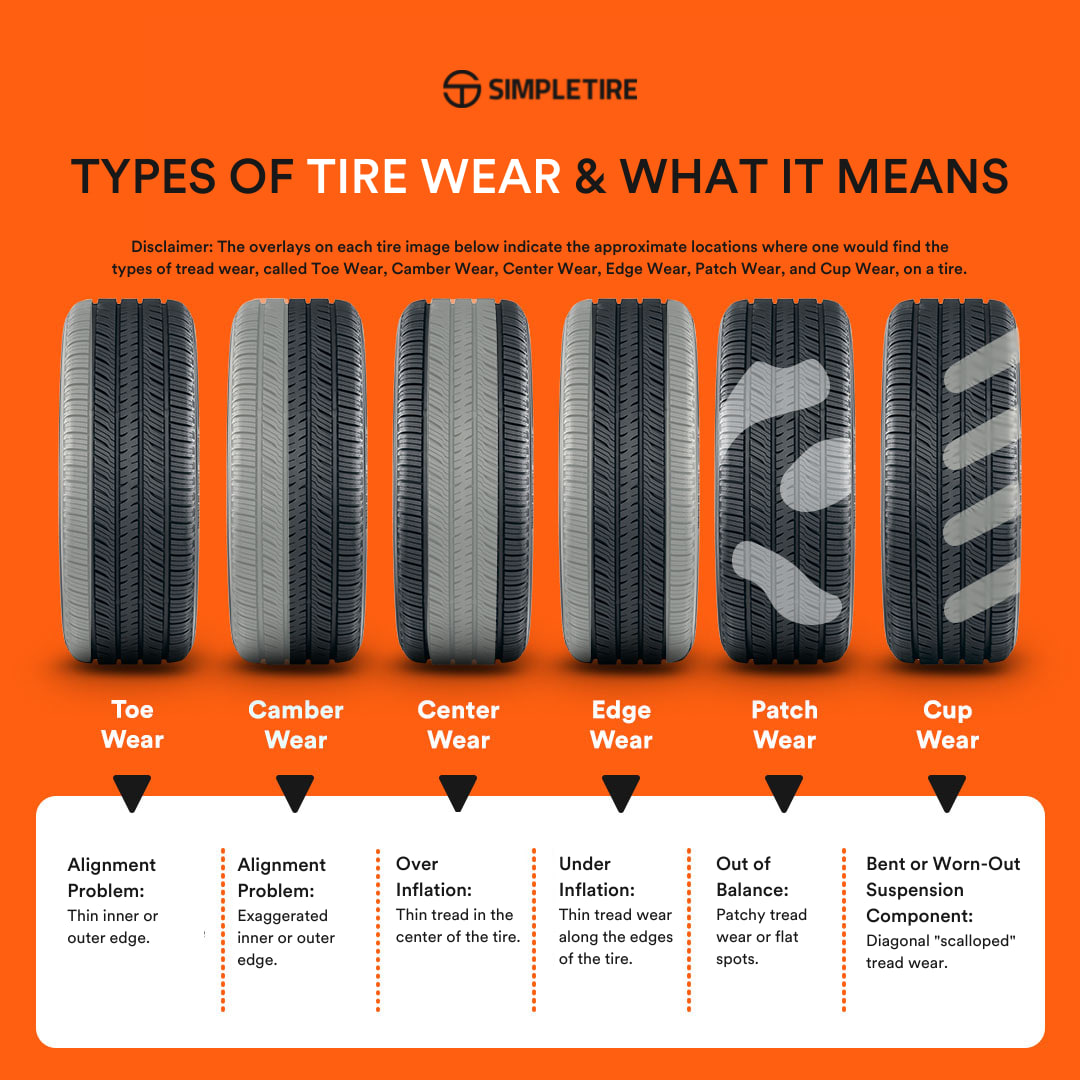

What does tire alignment mean? Your car leaves the factory with all four wheels set to specific angles for the best handling, road manners, and braking performance. A hard hit on a pothole or railroad tracks can be enough to jolt a wheel out of spec, and older vehicles with worn suspension and steering parts can end up with a “drift” out of alignment. Vehicles with poor wheel alignment will have symptoms such as:

- Persistent pull to one side while driving on flat, straight, un-crowned roads

- A need to hold the steering wheel off-center to continue in a straight line

- The steering wheel doesn’t return to center readily after rounding a corner

- The steering feels heavy and clumsy like you’re driving a loaded dump truck

A wheel that’s out of alignment will “try” to guide the vehicle in a different direction while you’re headed in a straight line – with that wheel skewed to one side, it will also scrub off the tire’s tread prematurely along the inside or outside shoulder. If a front wheel is off its alignment angle by only ⅛” and you go one mile down the road with no correction, it would steer you somewhere 28 feet off the pavement by the end of that mile! A good alignment shop or dealership can use an alignment rack and laser tools to make fine adjustments and correct wheel alignment problems. We should also mention that the manufacturer's tread life warranty will not cover a tire that’s prematurely worn due to alignment problems.

R: Rotate your tires at the manufacturer’s recommended intervals

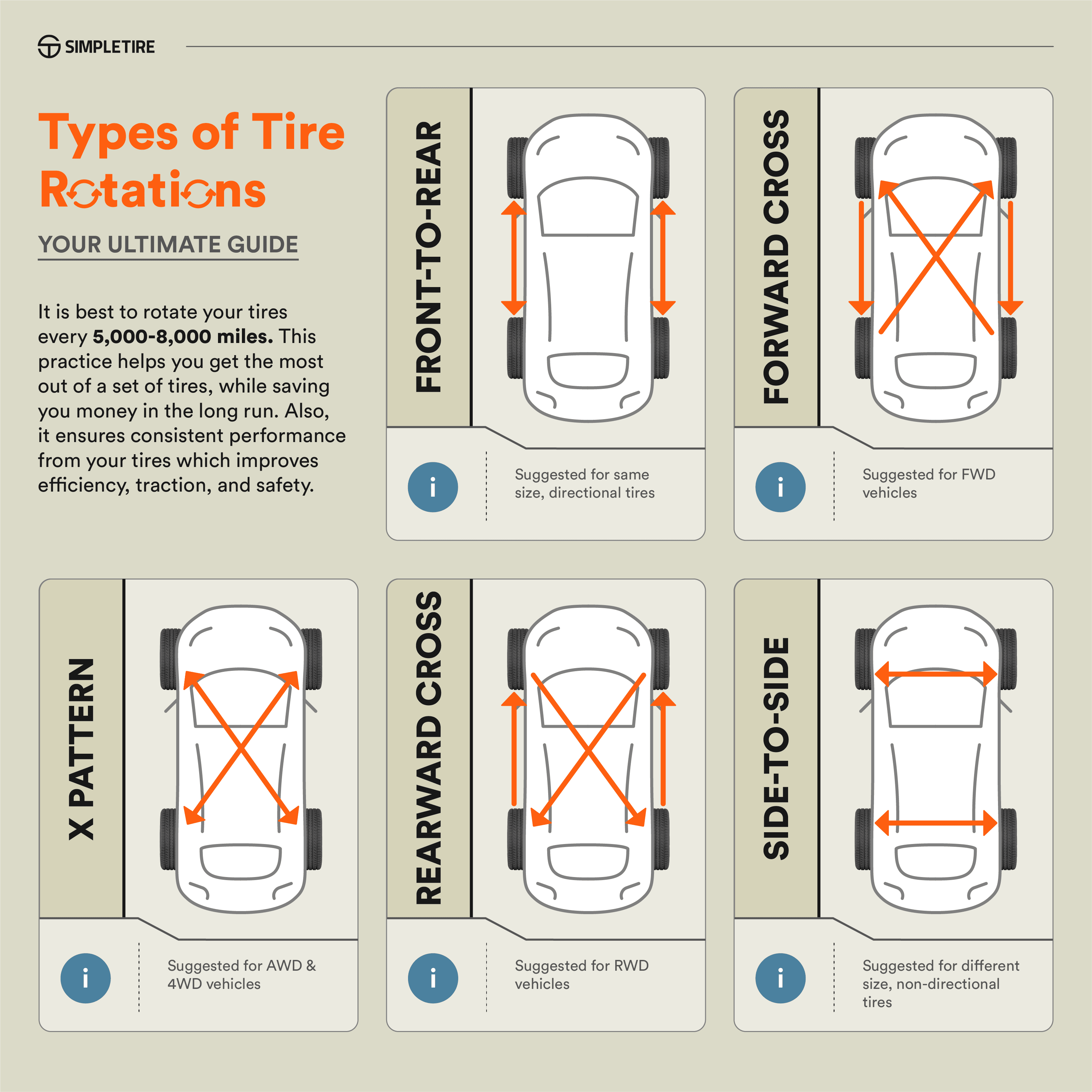

No vehicle has a perfect 50/50 weight distribution, and braking and cornering forces shift the vehicle’s weight forward as inertia and momentum have to be arrested. That (along with engine weight over the front wheels) means your vehicle’s front tires are under undue stress and wear. To equalize that wear, tires must be rotated front-to-rear at 5000-7000 mile intervals, per the tire manufacturer’s advice. Not rotating tires regularly will cause premature wear that won’t be covered by warranty. Some vehicles and tires can be rotated in an X pattern, while others need to be swapped front to back; check with your tire shop, but don’t put off rotations.

T: Tread, as in “inspect the tread of your tires regularly”

In every state, the minimum tread depth is 2/32”. Most tires have wear bars molded into the base of the tread at a right angle to the grooves; these wear bars are 2/32” tall, so they appear when tires are worn down to that depth. There are better ways to check your tread depth than that, though.

The penny test is when you take a penny and insert it into your tread grooves with the Lincoln Memorial facing you. If the rubber reaches the bottom of the memorial, your tread depth is around 6/32”. If the rubber doesn’t reach the memorial, stick a quarter into the tread grooves with Washington’s head pointed downward and facing you. Does the rubber reach the top of Washington’s head? That’s a tread depth of 4/32”. Now, to determine minimum tread depth, try again with a penny, Abe’s head pointed down and facing you. If the tread only reaches the top of his head, then your tread depth is down to 2/32” and you need to replace your tires soon.

Tread depth isn’t the only concern here, though. You should also inspect your tread for cuts, punctures, foreign objects, and evidence of separation or protruding belts or cords. Run your hand lightly over the tread face and feel for a sharp edge or “sawtooth” effect that can point to suspension problems. Look closely for any signs of uneven wear at the inner or outer shoulder, which can indicate alignment issues. Also, look at your sidewalls for bulges, scuffs, and any other evidence of damage.

These are all pretty easy tasks that don’t take much time, but drivers overlook them far too often, sometimes with bad consequences. Let’s dig in and look deeper into why tire maintenance is so important.

Why trucks need different tires

Whether you’re talking about all-season tires, winter tires, performance tires, or any other type of automotive tires, they’re all designed differently. Tire manufacturers’ design teams engineer their products around the weight, center of gravity, horsepower, torque, handling characteristics, braking performance, and suspension of specific vehicle types. That and dozens of other variables are all baked in the cake to deliver the kind of ride quality, handling and cornering ability, braking, noise levels, and road manners drivers are looking for.

In the case of tires for light trucks and SUVs, all those variables are considered. Even for all-season or highway-terrain light truck tires that might never go off the pavement, they’re designed with more durable tread compounds, stiffer sidewalls reinforced internal construction with more robust ply layers and steel belt packages, and more aggressive tread patterns (often with deeper grooves for improved traction and longer wear). Some light truck tires might even use a material like DuPont Kevlar for one of the belt layers (the same Kevlar used in body armor and ballistic vests) for an added measure of durability.

Pickup trucks and SUVs usually have a higher curb weight than most sedans, minivans, and smaller crossovers, but they’re also expected to haul loads and/or tow trailers. Any tire that will be called on for that kind of duty needs extra durability to support not just the vehicle's weight but the payload demands that go with it. And, of course, all-terrain tires need to be tough enough to handle rocks, logs, debris, obstacles, and a lot more challenging treatment overall than highway-terrain tires for light trucks (while still delivering confident traction in mud, loose dirt, gravel, sand, snow, etc). Long story short, light truck tires are much more durable and heavy-duty than automotive tires. Unfortunately, the tradeoff that goes with that is that, in many cases, the stiffer sidewall and more rigid tread area of light truck tires might mean ride quality that’s less refined and forgiving than automotive tires.

What is load index, and why does it matter?

Load index is coded information that lets a driver know how much weight a tire can safely handle when properly inflated without overheating, stressing the tire itself, or causing handling and braking problems for the vehicle. Whether it’s a sedan, minivan, crossover, big pickup, or SUV, choosing a tire with a lower load index than the tires that came with the vehicle will mean that the tire will not be able to safely, dependably support, and manage the weight of the vehicle.

The tire industry developed the load index code decades ago; this numerical code goes from 0 to 100 for most applications, with a 0 load index supporting 99 pounds and a load index of 100 rated at 1764 pounds. The load index goes up to 150, for an astonishing 7385 pounds. Still, those heavy load indexes will be for tires for earthmovers, tractor-trailers, and other commercial or off-the-road applications. Remember, though, that rating is weight per tire, so you’ll need to figure out how to multiply that by four and see if that corresponds to the gross vehicle weight rating (GWVR) of your vehicle.

This information can be found in your vehicle’s owner’s manual or on the tire info sticker on your driver’s door sill or under the hood, taking the guesswork out of the equation. Overloading tires is never a good idea, as it can affect handling, braking, and ride quality and possibly lead to premature tire wear or tire failure. Go with the recommended load index for your vehicle’s tires, which is also figured into the tire finder resource in tire retailers’ websites or brick-and-mortar stores.

What is speed rating, and why does it matter?

As the name suggests, a speed rating is a code that will indicate the highest speed a tire can handle and still safely perform as designed. Speed ratings are coded from A to Y, with A being a 3 mph rating and Y-rated tires capable of 186 mph. Exceeding a tire’s speed rating can affect handling, braking performance, and overall safety – in some instances, a tire might not be able to hold together. It could fail at high speeds (obviously not something you want to have happen, ever). Automakers will generally opt for a tire with a higher speed rating than the top speed a vehicle can reach for an extra margin of safety.

Like load index information, tire speed ratings can be found in the owner’s manual or on a sticker that could be found in the owner’s manual, glovebox lid, door frame, or inside the gas tank hatch. Again, the tire’s speed index is part of the information that is in the tire finder resource on tire retailer websites or at a brick-and-mortar tire store.

How plus sizing impacts tires

Plus sizing is when you opt for a bigger rim size and tire size than what the vehicle was equipped with from the factory or go with a wider rim and tire than the original equipment. Plus sizing might be done for performance reasons or just for style and appearance, with diameter increased anywhere from one to eight inches. Plus sizing can come with some definite advantages and drawbacks:

PROS:

- A wider set of tires puts more rubber in contact with the road, enhancing traction, stability, and cornering performance. Wider tires have been a pretty common modification for performance cars for decades.

- Wider tires give a vehicle a more aggressive stance and a sportier, tougher look.

- Low-profile tires with a shorter sidewall height tend to have lighter, more responsive steering and enhanced cornering ability.

- Wider tires can offer enhanced braking performance, with a bigger contact patch to help shut down a vehicle’s forward momentum faster.

CONS:

- Taller rims and tires can interfere with a vehicle’s speedometer readings, ABS, and stability control.

- Taller rims and tires can (in some cases) put undue strain on wheel bearings, spindles, and suspension components.

- Low-profile tires with a shorter sidewall height can be more vulnerable to potholes and make the vehicle’s rims more prone to damage. Alloy or forged wheels are expensive!

- Larger rims and tires can put undue stress on the wheel studs and lug bolts.

- Low-profile tires have less sidewall area to soak up vibrations and roughness for a firmer and less forgiving ride.

This isn’t to say that plus-size wheels and tires are a bad idea since they can improve a vehicle’s performance in some respects. However, you should know what you’re getting into with a project like that and get expert advice because there’s a right and wrong way to go with plus-size wheels and tires.

Most common truck tire types

Here are the kinds of tires you’ll commonly find on today’s light trucks and SUVs:

- All-season tires: Aside from a reinforced structure and more heavy-duty tread compound for a truck’s added weight, all-season truck tires have much in common with automotive all-season or Grand Touring tires. They’re designed for year-round traction, a quiet and refined ride, capable and predictable handling, good road manners at highway speed, and good wear properties, usually with a lengthy limited manufacturer’s tread life warranty.

- Highway-terrain tires: Highway-terrain tires are similar to all-season tires. They have the same performance targets and heavy-duty construction, which gives them a better load rating and durability. These tires can be a good choice for commercial applications such as route trucks or service trucks.

- Winter tires: Like automotive winter tires, light truck winter tires are purpose-built for traction in snow, slush, and ice. That means a softer, more pliable tread compound that stays flexible for traction in subfreezing weather and a tread design that includes grooves, sub grooves, angled grooves, and sipes that are all designed to multiply the tread’s surface area and traction and easily claw through snow and slush. Some winter tires are also pre-drilled for easy installation of metal or plastic studs in case of ice (always check state and local laws for restrictions and legality of studded tires).

- All-terrain tires: The best all-terrain tires for light trucks deliver durability and off-road traction on difficult terrain, along with road manners, handling, ride quality, and noise levels that are refined and composed on pavement. All-terrain tires will have enhanced tread formulations for better damage resistance, tougher internal construction, and lug or block tread with a wide void ratio, meaning wider grooves that can dig into mud or dirt but can also easily eject it as the wheel turns, ensuring there’s always a clear section of the tire to dig in.

- Mud-terrain tires: Mud-terrain tires take the design of all-terrain tires and up the game for extreme conditions like deep, sticky mud. They’re more damage-resistant, have a more aggressive tread, and can be used “aired-down,” with low inflation pressure so that the tires can conform to rocks, logs, and other obstacles as they grapple their way through steep, difficult terrain. Due to their size, mud-terrain tires also tend to be noisier, difficult to balance, and clumsy in their handling on pavement.

- Rugged-terrain tires: Put simply, rugged-terrain tires split the difference between all-terrain and mud-terrain designs. They’re designed for performance in situations where all-terrain tires might fall short, and many are designed specifically for enhanced winter performance in snow and slush. Many rugged-terrain tires have the tire industry’s 3 Peak Mountain Snowflake certification for severe winter service.

Most common truck tire sizes

We should highlight the difference between P-Metric and LT tire sizes for light trucks. Many trucks leave the factory with P-Metric-size tires as OEM; they’re generally more light-duty, prioritizing ride comfort, road performance, and long wear. Many P-Metric tires also are designed for low rolling resistance, helping to enhance fuel economy. Generally, LT sizes are more durable and designed for enhanced load rating; the two classes of tires aren’t exclusive, though P-Metric tires can be swapped for LT or vice versa.

Even though the tire sizes and rim sizes on light trucks and SUVs keep getting bigger, the most common sizes for truck tires are:

Maintenance isn’t a one-week project

National Tire Safety Week might be one week per year, but it’s important to practice good safety habits with your car and tires year-round. Regularly checking your tread, rotating your tires, inflating them to the correct pressure, practicing safe following distances, changing your oil, and many other things go into keeping your ride in tip-top shape.

Fortunately, many tire manufacturers are finding innovative ways to make maintenance easier on drivers and to make tires that meet and exceed drivers’ needs.

Ready to find the perfect tires?

Search By